Antimicrobial Coatings

In our daily lives, we encounter numerous surfaces that harbor unseen threats in the form of bacteria and other microorganisms. To combat this pervasive issue, the rise of antimicrobial coatings has become a notable solution. But what exactly are antimicrobial coatings, and how do they work?

This article provides an introduction to the world of these protective layers to understand their significance better.

What is an Antimicrobial Coating?

Antimicrobial coatings are specialized layers applied to surfaces to inhibit the growth and spread of microorganisms. Unlike regular coatings, antimicrobial formulations actively combat bacteria, viruses, fungi, and other harmful microbes, promoting a safer and cleaner space.

These coatings can take the form of traditional wall paint, wood varnishes, spray coatings for metal, dip coatings for medical devices and so on.

Difference between Antimicrobial, Antibacterial, and...

Before delving into antimicrobial coatings, it’s crucial to distinguish terms: antimicrobial, antibacterial, and antiviral—often used interchangeably. While antibacterial focuses specifically on bacteria, antimicrobial is a broader term encompassing bacteria, viruses, fungi, and more. Understanding these distinctions is key to appreciating the diverse protective capabilities of antimicrobial coatings.

How Antimicrobial Coatings Work:

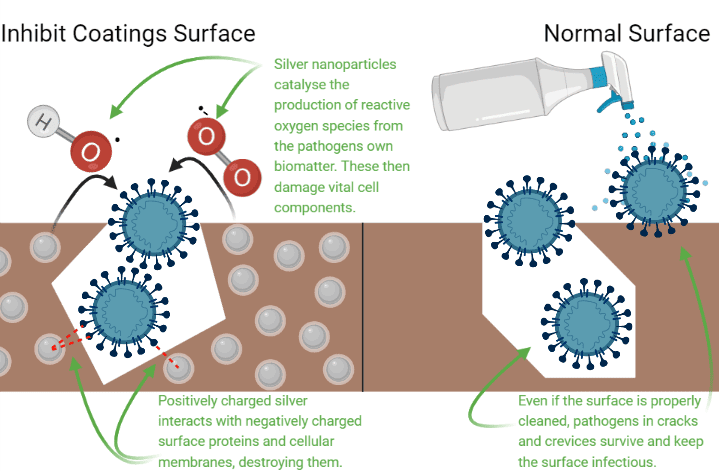

The efficacy of antimicrobial coatings lies in disrupting microorganisms’ lifecycles. These coatings incorporate agents that interfere with microbial cellular structures, preventing multiplication and causing harm. The specific method of action varies: some coatings employ physical means, puncturing the cell walls of bacteria, while others disrupt crucial metabolic processes. The outcome is a surface that actively thwarts microbial colonization, establishing a robust and enduring defense against contamination.

The choice of active ingredients plays a pivotal role in determining the overall performance, longevity, and cost-effectiveness of antimicrobial coatings. Different active agents exhibit distinct mechanisms of action, influencing how effectively they combat specific types of microorganisms.

Additionally, the incorporation of these agents into coating formulations can impact the coating’s durability over time. If you would like to learn how Inhibit`s antimicrobial technology works to create long-lasting, cost-efficient, and highly effective coatings please click HERE.

The Need for Antimicrobial Solutions:

Microbial contamination presents substantial threats to public health and safety, spanning environments from hospitals to public transportation, where the risk of infection spread remains constant. Traditional cleaning methods, while effective to a certain extent, have limitations. This underscores the crucial need for antimicrobial solutions, providing a proactive strategy to curtail disease transmission and uphold hygienic conditions.

Beyond immediate health concerns, microbes exert damaging effects on diverse products across industries like textiles, electronics, and everyday items. Their activities contribute to material degradation, corrosion, and unpleasant odors. In this scenario, antimicrobial coatings emerge as protective shields, countering these destructive forces Addressing health and product durability simultaneously, antimicrobial solutions emerge as versatile safeguards against the intricate challenges posed by microbial contamination.

Where Antimicrobial Coatings are Applied

Antimicrobial coatings find extensive applications across diverse sectors. In healthcare, they mitigate the risk of hospital-acquired infections. The food industry employs these coatings to uphold hygiene standards on surfaces. Notably, public spaces, residential areas, and personal items like smartphones now enjoy the safeguarding benefits of antimicrobial coatings, fostering a safer environment.

For details on the industries we serve, please explore further.

Preserving products with Antimicrobial Coatings:

Antimicrobial coatings play a vital role in prolonging product life, especially in textiles. These coatings act as shields against mold growth in industries like apparel and home textiles, preserving fabric integrity and ensuring freshness over time.

Beyond textiles, antimicrobial coatings significantly enhance product durability in various sectors. In electronics, these coatings protect against microbial-induced corrosion, while in everyday items, they prevent material degradation. This not only extends product life but also aligns with sustainability goals by reducing the need for frequent replacements, minimizing environmental impact.

As we navigate a world focused on responsible consumption, antimicrobial coatings prove essential, not just for health.

For more examples, please visit our product page.

How Long do Antimicrobial Coatings Last ?

The durability of antimicrobial coatings hinges on factors like formulation, application setting, and active ingredient type. Typically, these coatings aim for robust, long-term defense, with some offering efficacy for months or even years.

However, external factors like harsh conditions or frequent abrasion can impact effectiveness. Some active ingredients may leach, especially in environments with rigorous cleaning or exposure to harsh chemicals.

Understanding these dynamics underscores the importance of periodic assessments and potential reapplication for sustained protection. Inhibit Coating exemplifies lasting antimicrobial protection, as demonstrated by a trial in a high-risk area of a food processing plant, where effectiveness persisted for over 4 years.

The Future of Antimicrobial Coatings

The antimicrobial coatings market experiences robust growth, driven by heightened awareness of their role in hygiene and safety. This surge extends across healthcare, food processing, public spaces, and residential settings, reflecting a societal shift towards proactive microbial control. Regulatory standards emphasizing infection control further contribute to this expansion. As antimicrobial solutions become more cost-effective, their usage in consumer products is expected to rise. The USA market is the largest, with the Asia Pacific being the fastest-growing region in this dynamic market.

Please feel free to contact us if you would like to understand further how antimicrobial technology can be added to your products. If you would like to stay updated with our latest developments you can follow us on LinkedIn.